Safe and Efficient Technology.

Automated trailer unloading and loading that works. Fox Robotics’ Autonomous Forklifts are delivered and installed in just one hour.

Our robots work quickly–unload a full trailer in 45 minutes or less.

Standards for Forklifts & AMRs

The FoxBot is designed with safety standards for both forklifts and automated mobile robots. Each robot is built to and compliant with ANSI/ITSDF B56.1 for “E” industrial trucks. Manual operation is supported, allowing direct operator control at any time.

Manual operation is supported, allowing an operator to take direct control at any time.

Loading & Unloading

We start with a standard 3-wheeled counterbalance electric forklift and equip it with a suite of safety-certified, off-the-shelf sensors and proprietary firmware to enable precise navigation and robust pallet-picking capabilities.

Our autonomous forklift operates on the receiving docks of customer warehouses, with real-time vision and LiDAR perception of the warehouse space around it.

A Fox Robotics deployment engineer will bring a robot onsite to pull trailers for 12 weeks and train your operators to use the FoxBot ATL, following data analysis and recommendations for your business.

FoxBot ATL In Operation

Automated Peace of Mind

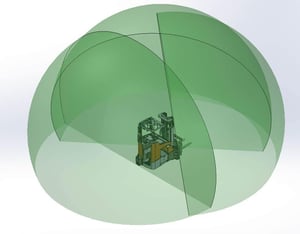

Our robots continuously monitor the space in 3 dimensions around them, checking for obstacles and stopping in advance of collisions.

3D LiDAR sensors, cameras, Programmable Logic Controllers (PLCs), Safety Relay, and fully redundant safety braking work together to avoid collisions and keep workers safe.

Every FoxBot is programmed to follow standard driving etiquette and safety procedures and to sound its horn before entering and exiting trucks.

Possibly unlike human drivers, the FoxBot strictly adheres to speed limits and safety protocols.

You decide where the FoxBot is allowed to go and stay when not in use.

When using the FoxBot, fewer warehouse employees are in harm’s way.